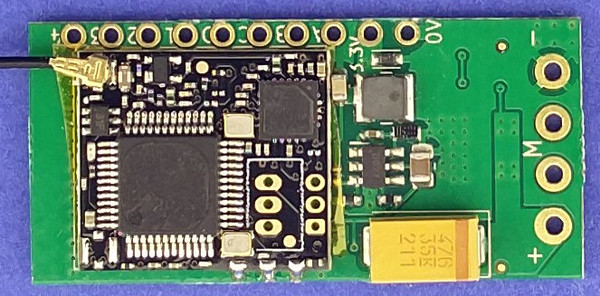

MR603b Bottom

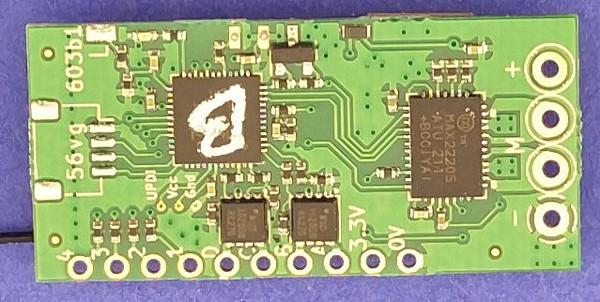

MR603b Top

The MR603 receiver is designed for use in larger scale

model rail locomotives and road vehicles.

It provides a 3A reversible ESC for brushed motors and 10 auxiliary

outputs for lighting, sound triggers, couplers, etc.

It operates on 2.4GHz and is compatible with any Spektrum DSM2 or DSMX

transmitter including all of the Micron

model rail transmitters.

The voltage range is 5V to 20V.

MR603 requires binding with your

transmitter before use.

If purchased with a transmitter, it will be already bound to that transmitter.

Once bound, the transmitter should be switched on before the MR603.

If the transmitter is not switched on, MR603 will automatically enter

bind mode 10 seconds after switch on; it may also be configured

to bind only manually using pads P5 and P6.

The MR603 free-air range, when used with a Micron low-power transmitter,

is 40m-50m and approximately 200m when used with

a full-power (100mW) transmitter.

This range will be reduced indoors due to absorption by furniture / fittings

and reflections from metal surfaces.

Range is also reduced if the receiver aerial is in a metal enclosure.

Ideally, the aerial should be placed outside the vehicle body and clear of

any metal.

The active tip of the extended aerial needs to 'see' the transmitter so

should be placed through a hole in the vehicle body - e.g. into the cab space.

The MR603 aerial should not be cut short or made longer as this will

affect operation of the receiver.

It is important to perform a range check after installation to ensure

you have full control of your loco/vehicle at all positions around the layout.

Features (top)

- Compatible with all DSM2 and DSMX transmitters with up

to 10 R/C channels, both Micron

model rail and aero model stick type transmitters.

- 5V to 20V working voltage range.

- 10 auxiliary outputs: 4 x 'F' which are normally open switches

capable of passing up to 2A; and 6 x 'P' which are 0V/3.3V logic outputs

capable of supplying up to 20mA each. P outputs may also be configured

to drive servos.

- Supports the Selecta feature

for compatibility with multi-loco transmitters, MR603 must

be re-bound to change Selecta switch position.

- 4 pre-installed configurations providing a usable set of

receiver output to transmitter control mappings - see

Configurations (end of document).

When switched on, the receiver LED shows a flash pattern

to indicate which configuration is selected.

- Most pre-installed configurations provide auto-switched front and rear

LED lights on P1 and P2 or F1 and F2

- The receiver on-board LED can be repeated to any non-servo output

(this is called the LED2 function).

- Cruise control is enabled by default - the motor keeps running if

the transmitter signal is temporarily lost. Can be disabled

using a power-on configuration change or by programming.

- All functionality may be configured by programming using a

suitable transmitter (most Micron tx or a stick type

model aircraft tx).

Usage (top)

- Do not bend the receiver circuit board

- Connect the positive and negative input pads to a suitable battery or

power supply, via a on/off switch in the positive lead.

A resettable fuse must be placed in the battery positive lead

to protect the battery in the event of a wiring or component fault.

- Connect the 'M' pads to your vehicle motor, removing any connections

to track pickups. The motor should be fitted with suppression

capacitors to avoid injecting excessive electrical noise

into the receiver; 100nF across the motor terminals and 100nF from each

terminal to the motor case. If symptoms of motor noise interference

persists, 10uH chokes in each motor lead usually solves the problem;

the chokes must be rated for the maximum motor current.

- Connect any auxiliary circuits to the F and P pads; the 3.3V pads may

be used for powering auxiliary circuits with a maximum of 20mA per pad.

- Protect the receiver board before applying power for testing.

It must not be allowed to touch anything metal.

If MR603 was purchased with the heatshink cover supplied loose,

slide this over the circuit board.

- MR603 requires binding to a transmitter before use;

if purchased with a transmitter, it will be ready bound

(at Selecta pos #1, if the transmitter has a Selecta switch).

- After switching on:

- the CPU LED will emit a rapid flash followed by a flash count

corresponding to the selected configuration (default = 1), shown

twice

- the CPU LED will then slow flash while MR603 is searching for

its bound transmitter; if not already bound, approx 10 seconds

later the receiver will go into bind mode and the RF LED will

show a rapid flash

- When bound:

- the CPU LED will be on to show receipt of good data

from the transmitter

- the RF LED will be on and may flicker due to electrical (e.g

motor) noise, signal

fades caused by reflections,

interference from WiFi or Bluetooth signals,

or overloading from the transmitter (this will happen if the

transmitter is too close)

- the CPU LED will show a repeated double flash when deselected

(transmitter Selecta switch is moved)

- the CPU LED will show a repeated 5 flash if the low voltage

cutoff has triggered

- After testing, apply the heatshrink cover if not already fitted.

- Fix the receiver in place and route the aerial so that the last

30mm can 'see' the transmitter for best range.

Double sided foam-cored sticky tape is ideal for mounting the receiver.

Connections (top)

MR603 has solder pads for:

- power input (positive & negative battery)

- motor output

- 3.3V from the on-board regulator which can supply a max of 200mA

- an additional battery negative connection (0V) - useful for wiring

LEDs to P pads

- L: used to monitor battery voltage when

a booster module is used, e.g. to raise a single LiPo cell to 12V.

- P1..P6: these are logic level outputs, 0V when off and 3.3V when on;

they can be configured for on/off switching or to output a servo signal;

P5 and P6 are at the opposite end of the board to the battery

and motor pads, a 4 pin JST-SH socket may optional be fitted to

carry these P outputs plus 0V and 3.3V

- F1..F4: these are FET switches capable of up to 2A;

they are open circuit when off and

connected to battery negative when on; a load should be wired

between the F pad and battery positive, or the 3.3V pad for low

current loads; labelled A..D on the receiver board and

numbered 7..10 for programming

The power input and motor output pads have a 3.5mm spacing which allows

use of a screw terminal (optionally available when MR603 is purchased).

The long side pad spacing is 2.54mm which allows a pin header to

be attached if plug connectors are preferred for the F and P outputs.

A JST-SH 4 pin socket may optionally be fitted for P5, P6, 3.3V and 0V.

LEDs on P pads should be connected between the pad and battery negative (0V)

with a series resistor appropriate to the required brightness.

P1 to P4 have a series 180 ohm resistor on the PCB, P5 and P6 have

no resistor.

LEDs or incandescent lamps on F pads should be connected between the pad

and battery positive or the 3.3V pad and with a series resistor appropriate

to the voltage and required brightness.

Sound card inputs are usually 5V open circuit and are triggered

when connected to negative. They should be connected to an F pad.

A P pad may be used if you have more trigger inputs than F pads, or

a P to F converter is available from Micron - this is a small board

containing 1, 2, 3 or 6 FET switches.

If the P output is used directly for sound card trigger,

a 4k7 ohms resistor must be connected in series to avoid stressing

the MR603 microprocessor; the P output should be configured for 3.3V

idle and 0V when the Tx control is actioned.

Take care when soldering wires to P1..P4 and F1..F4 (A..D) as the pads

are very close the radio sub-board. The recommended technique is to fill the

pad hole with solder and then attach the wire to the top of the pad

on the side opposite to the radio board - i.e. don't pass the wire

through the pad hole.

Low Voltage Cutoff (top)

MR603 can be powered from a battery of 5V up to 20V. The speed

controller will stop the motor if the battery drops below 5V but the

other receiver functions will continue to operate down to 4V.

The default receiver setting is for the Low Voltage Cutoff (LVC)

threshold to be determined from the voltage measured at switch on.

This is auto mode which is essential when the receiver is powered using

a Lithium battery (LiPo or LiIon) as these must not be discharged

below 3V per cell.

The algorithm used for this calculation

means that a 9V Alkaline or NIMH battery can often be interpreted

as an almost discharged 3S LiPo.

The solution is to either disable LVC, or set it to the correct value

for your battery.

Switching between auto and disabled can be done using a

power-on configuration change

and the LVC threshold can be set to a specific value by

programming

the receiver.

Indicators (top)

MR603 has 2 LED indicators, one on the top near the aerial and another

on the bottom, these are labeled 'RF LED' and 'CPU LED' on the diagram:

- RF LED:

- lights continuously when a good signal is received,

flashes rapidly when the receiver is in bind mode and

flashes intermittently if signal is poor (transmitter too close

causing overload or transmitter too far away)

- CPU LED:

- indicates the receiver status:

- immediately after switch on, emits a 0.5s rapid flash

followed by a flash pattern to show the active configuration (1..4),

repeated once: e.g. rapid-flash, pause, 2-flash, pause 2-flash

shows that the receiver is using configuration #2

- flashes slowly while waiting for a good

transmitter signal

- lights continously when a good R/C data is being decoded

- flashes twice, pause and repeat when the receiver

is deselected (see Selecta)

- used for feedback when programming;

feedback flash patterns comprise a repeated number of flashes

followed by a 1 second pause - this is called a N-flash where N is

the number of flashes, e.g. 3-flash is 3 short flashes,

1 second pause and repeat

- shows a 5-flash if the low voltage cutoff has triggered

- this stops the motor but other outputs continue to work

Error Codes:

If the receiver firmware detects a fault,

all functions are disbled and the CPU LED will

display a repeated pattern of 0.5 seconds

rapid flashing followed by a N-flash where N is the error code

| Flash Count | Error |

|---|

| 1 | Rx firmware failed startup checks |

| 2 | radio transceiver failed initialisation |

| 3 | failed to read or write the configuration data |

| 4 | failed to write the configuration backup |

| 5 | failed to restore configuration from backup |

| 6 | a port (P or F output) is in an unexpected state |

If your receiver displays an error code, cycle the power and contact Micron

if the error persists.

Binding (top)

MR603 must be bound to a transmitter before use. Once bound, MR603

remembers the transmitter identity and searches for this when it is

switched on.

To bind a receiver, it is switched on with no transmitter active

(for normal operation, the transmitter should

be switched on before the receiver).

The default MR603 configuration is for autobind where the

receiver automatically goes into bind mode approx 10 seconds after

switching on with no pre-bound transmitter active.

Manual binding may be configured by programming - this could be useful,

for example, if the loco is to be used by children who could forget

to switch the loco/receiver on first.

- auto bind:

- The receiver enters bind mode approximately 10 seconds after power-on

if it has either never been bound or it fails to find its

bound transmitter.

- manual bind:

- Pads P5 and P6 must be connected before switching the receiver on.

If P5 and P6 have no soldered connections and the JST-SH socket

is not installed,

this can be achieved using needle nose tweezers pressed onto the pads.

Alternatively, and necessary when the receiver is inaccessible, a switch

can be wired to P5 and P6.

Bind mode is indicated by a rapid flashing of the receiver RF LED

and the following steps should be followed to bind with your

transmitter:

- transmitter switched off

- if Selecta

is enabled, move the transmitter loco selection switch to

the required position

- switch on the receiver in bind mode (manual or auto)

- only when the RF LED is flashing rapidly, hold down the

transmitter bind button and switch on

- wait for the transmitter to indicate that it is in bind mode and

then release its bind button (the power LED on Micron model rail

transmitters will flash when binding)

- after a short delay, the RF LED should stop flashing and

go dark and, after another 4-5 seconds, both RF and CPU LEDs will

light and stay on

- the receiver is now bound to the transmitter

If the receiver RF and CPU LEDs do not come on solid (no flash)

within 10-15 seconds, the bind process has failed.

This can happen for several reasons and does not normally indicate a fault.

During binding, the receiver searches for

the transmitter's signal and this can be distorted by holding the transmitter

and receiver too close.

So, if you get a bind fail, try again after moving them slightly further apart

or changing the relative orientation of the aerials.

Binding is most reliable when no other 2.4GHz transmitters are turned on.

Loco Selection - Selecta (top)

Many Micron model rail transmitters have a 12 way switch to allow control of up to 12 locos - Deltang originated this feature and called it 'Selecta'. Using the switch, locos are brought under control one at a time. When not selected, receiver outputs hold their current setting (e.g. a loco which is moving when deselected keeps moving) and the LED shows a 2-flash pattern. The default 'keep going' behaviour can be changed to stop when deselected by programming the receiver.

The Micron implementation of Loco Selection / Selecta is fully compatible with the Deltang Selecta feature and uses R/C channel 2 by default. When Selecta is enabled, the controlling R/C channel (e.g. 2) may still be mapped to a receiver output but, of course, this will not change as the transmitter switch is rotated.

The receiver has a 800ms delay before enabling when the transmitter Selecta value is changed. This is to avoid obeying the transmitter while the Selecta switch is being moved - e.g. a receiver on Selecta #4 should not change any outputs while the transmitter Selecta switch is moved from #3 to #5.

Selecta may be enabled by default (see the receiver configuration information) and may be enabled or disabled by using a power-on configuration change (see Power-On Configuration Changes) or by programming.

If Selecta is enabled, the transmitter's Selecta switch value will be saved when the transmitter and receiver are bound. A new Selecta value (i.e. switch position) can be stored either by rebinding or by using the power-on changes to disable and then re-enable Selecta.

Note: when the Selecta switch is changed to control a different loco, the newly selected loco responds to the transmitter control settings. The current range of Selecta enabled transmitters have no model memory so cannot have different throttle settings, etc. for each loco. Thus, although Selecta may be used to manage many moving locos, this must be used with care and is not recommended. Micron intends to introduce a transmitter with model memory but the release date is not known.

Directional Lighting (top)

Most configurations have

pads P1/P2 or F1/F2 setup to drive front and rear LED lights;

P1/F1 powers a forward LED and P2/F2 a backward facing LED.

The directional lighting pins can be changed

by programming the receiver.

MR603 has an on-board 3.3V regulator and 180 ohm resistors in series

with the P1 to P4 so limits the LED current to approximately 20mAh.

Most high brightness LEDs require much less than this so an additional

resistor should be used - e.g. 100 - 1k ohms.

The LED should be connected between P1/P2 and battery negative (0V)

or between F1/F2 and either the 3.3V pad or battery positive (with

and appropriate value series resistor).

The directional LEDs follow the throttle channel if configured for

centre-off, changing when the throttle passes though the off position.

If the throttle is configured for low-off, the LEDs change only

when the throttle is at zero - i.e. the direction control can be altered

at any time but the LEDs (and motor direction) changes only when

the throttle is closed.

The throttle mode (centre or low off) can be changed by programming or

by using one of the power-on configuration changes

Cruise Control / Failsafe (top)

If the receiver loses the signal from the transmitter,

for example when going through a tunnel or behind a garden building

or some dense bushes, MR603 outputs hold their current setting

until the transmitter signal is reacquired.

The motor also continues running when a Selecta-enabled receiver

(see Selecta) is

de-selected.

This is a form of 'cruise control' which allows you to

switch off the transmitter if, for example, you are running the loco

round a continuous circuit.

Cruise control can be disabled using a

Power-On Change

or by programming.

If cruise control is disabled, the receiver will

'fail safe' and the motor will be stopped when signal is lost.

Emergency Stop (top)

Any of the transmitter controls can be used as an 'Emergency Stop' function

to rapidly bring the loco/vehicle to a stop.

Emergency Stop is not enabled by default and must be configured

by programming the receiver.

To enable Emergency Stop, you need to choose:

- the R/C channel

- whether a low or high signal is used to trigger

- the delay before stopping - i.e. the number of seconds that

the R/C channel must be in the trigger state before Emergency

Stop is actioned

For example, the Tx22X transmitter button S2 (in-between the 2 toggle switches)

could be used: this controls R/C channel 4 and the signal is low when

the button is pressed.

Power-On Configuration Changes (top)

A few configuration changes can be made without programming.

A simple link across 2 of the auxiliary P pads is used to action

the change. This is easily achieved using some needle nose tweezers

and, if they are sharp pointed, can penetrate the receiver's heatshink cover.

Do not use a paper clip as these often have burrs on the ends which can

damage the circuit board plating if inserted into a pad hole.

A change is made by:

- connecting the appropriate P pads with the receiver off,

- switching the receiver on and observing the LED flash pattern,

- removing the connection which is confirmed by a rapid LED flash and then

- switching the receiver off.

The changes all toggle (or cycle) the parameter value each time the

process is performed.

The LED flash indicates the new state of the configuration parameter.

The receiver has to be switched off after the change as it will be stuck

in the rapid flash mode to indicate that the change has been made.

If you switch off before removing the P connection, the

configuration is not changed.

This is a summary of the configuration changes that can be made using

a jumper across 2 of the P pads.

| Change | Pads | LED indication |

|---|

| Reset | P1/P2 | 2-fast-flash = reset to saved configuration, or factory setup if no configuration saved |

| Selecta | P1/P3 | 1-flash - disabled

2-flash = enabled |

| Cruise Control | P1/P4 | 1-flash = disabled, stop in 4s after signal loss

2-flash = enabled |

| ESC Throttle Mode | P2/P3 | 1-flash = centre-off

2-flash = low-off |

| Configuration Select | P2/P4 | n-flash where 'n' is the configuration number |

| LVC | P3/P4 | 1-flash = disabled

2=flash = enabled with battery voltage auto-detect |

P2/P4 'Configuration Select' requires further explanation.

Each flash count is repeated twice and then increments to the next,

cycling back to 1 when the max (usually 4) is reached.

Remove the P2/P4 connection when the flash count is the configuration

you want.

Note: any previous programming or power-on configuration changes

(e.g. LVC or throttle centre/low off) will

be over-written when a different configuration is selected and will need

to be done again.

Receiver Programming (top)

The behaviour for each MR603 pad (ESC, F or P) can be changed

using a bound transmitter.

MR603 must first be put into programming mode and then the

direction toggle switch, or elevator on a stick type transmitter,

is used to enter a program sequence one digit at a time.

The CPU LED (and LED2 if enabled) flashes to indicate the value of

the current step in the programming sequence. For example, if the

current value is 4, the CPU LED flashes 4 times, pauses and repeats -

this is called a 4-flash.

The programming table is large and presented in a separate

document (see micronrc.co.uk/mr6xx_progtable) which lists all of

the functions that may be changed by programming.

The table is split into 5 blocks of related functions each with the

same value in the first column.

The table columns contain the program values which must be entered to change

a particular function. For example, to change the throttle behaviour

from centre-off (forward and reverse on one control) to low-off

(separate throttle/regulator and direction/reverser controls)

the program sequence 1, 1, 2, 1, 3 is entered. Each digit of this

program sequence is taken from the columns, left to right:

1 = ESC Configuration

1 = H1 (there is only 1 ESC on MR603)

2 = Low Off Throttle

1 = Throttle on R/C channel 1

3 = Direction control on R/C channel 3

One function can be changed at a time. The general method is:

- set receiver into programming mode

- enter a program sequence

- repeat until all programming changes have been made

Enter Programming Mode

There are 2 methods of getting the MR603 into programming mode:

- switch the transmitter on and hold channel 2 and channel 4 controls at

high or low extremes and then switch the receiver on;

these are the F1 and F2 buttons on a Tx20v2

and the Selecta switch and S2 button on a Tx22X;

the receiver LED will flash rapidly shortly after switch on,

centre one or both channel 2 & 4 controls (e.g. release the buttons

on Tx20v2 or the S2 button on Tx22X

- switch the transmitter and receiver on (they must be bound),

wait 5 seconds without touching any controls and then tap out morse

SOS (... --- ...) on the transmitter bind

button (or toggle the gear switch high to low for a stick transmitter);

- dots (…) will be a quick press of the button and must be

less than 1 second in duration

- dashes (---) must be greater than 1 second and shorter

than 5 seconds – 2 seconds is a reliable time

- the time between each dot or dash must be less than 5 seconds

When programming mode has been successfully entered, the receiver LED

will show a 1-flash - this is the 1 from the first column

of the programming table.

If you do not get the 1-flash, repeat the procedure to enter

programming mode. It usually takes a couple of

attempts to get the SOS method correct if you have never done it before.

Enter a Program Sequence

One programming change requires up to five choices to be made.

These are called 'levels' and each has several options.

They are documented in the programming table.

Completion of a programming change exits programming mode and requires the

receiver to be placed into programming mode again for the next change.

It is a good idea to write the programming sequence on a piece of scrap

paper and cross off each digit as it is entered so that you

don't lose track of where you are in the sequence.

You always start at the top of the first column and 1-flash is

displayed on entering programming mode.

- The flash count for a level is incremented by setting the

R/C channel 3 control low and back to mid.

- The flash count for a level may be decremented by holding

the R/C channel 4 control low while operating the R/C channel 3

control; R/C channel 4 is available on some Micron transmitters

- e.g. F2 on Tx20v2 and S2 on Tx22X and TX42v2

- The level value is accepted and the flash count for the next

level is displayed by setting the R/C channel 3 control

high and back to mid.

Most Micron transmitters have a toggle switch on R/C channel 3

which is marked A/B, or forward/reverse for a low-off transmitter:

- pushing the switch down (or toward 'reverse' for a low-off transmitter)

sets the R/C channel to a low value and increments the flash count,

- pushing the switch up (or toward 'forward') sets the

R/C channel to a high value,

accepts flash count and moves the program sequence

on to next level or exit programming mode if the current level is

the last in the sequence

Always return the toggle switch to centre after pushing down or up.

Refer to the transmitter user manual for specific information

on the R/C channel 3 control - Tx24v2 has a rotary reverse control.

The receiver LED will flash rapidly while R/C channel 3 is high or low and

then return to a slower repeated flash when the control

is back to the middle.

After accepting the flash count for a level, the CPU LED displays

a flash count for the current value of the next level. This could be

higher than 1-flash if the function is set in the receiver configuration

or has been previously programmed. For example:

- the default Selecta R/C channel is 2, so a 2-flash will be

displayed after entering 4, 8, 2

- P1 is configured as a front light, so a 4-flash will be

displayed after entering 3, 1

When the last level for a sequence has been accepted, the CPU LED

will light continously and the receiver is back in normal operating mode.

The maximum number of levels is 5, but not all sequences use all 5;

if level 5 in the table is blank, the CPU LED will light continously

after level 4 is accepted.

Programming changes are accepted only when the CPU LED lights solid

at the end of the sequence.

If a mistake is made mid way through a sequence,

switch the receiver off to abort.

Programming Examples

These examples assume MR603 is in as-received configuration

and a Micron transmitter with toggle switch on R/C channel 3.

Tx24v2 transmitters have a variable control on R/C channel 3 - the Reverser;

the equivalent actions are:

| Action | Tx with toggle switch | Tx24v2 type transmitter |

|---|

| Increment flash count: | toggle down | Reverser fully CCW (reverse) and back to centre |

| Accept flash count: | toggle up | Reverser fully CW (forward) and back to centre |

- Set P4 as servo on R/C channel 7

program sequence: 2, 4, 1, 6

- enter programming mode

- LED shows 1-flash (level 1, 1=ESC)

- toggle down and release once,

LED shows 2-flash (level 1, 2=servo)

- toggle up and release,

LED shows 1-flash (level 2, 1=P1)

- toggle down and release 3 times,

LED shows 4-flash (level 2, 4=P4)

- toggle up and release,

LED shows 1-flash (level 3, 1=servo)

- toggle up and release,

LED shows 1-flash (level 4, 1=R/C chan 1 - P4 was prevously a

momentary on/off output)

- toggle down and release 6 times,

LED shows 7-flash (level 4, 7=R/C chan 7)

- toggle up and release,

LED shows 1-flash (level 5, 1=normal speed)

- toggle up and release,

LED lights continously and servo on P4 responds to R/C channel 7

- Reverse servo on P4

program sequence: 2, 4, 7, 1

- enter programming mode

- LED shows 1-flash (level 1, 1=core)

- toggle down and release once,

LED shows 2-flash (level 1, 2=servo)

- toggle up and release,

LED shows 1-flash (level 2, 1=P1)

- toggle down and release 3 times,

LED shows 3-flash (level 2, 4=P4)

- toggle up and release,

LED shows 1-flash (level 3, 1=normal servo)

- toggle down and release 6 times

LED shows 7-flash (level 3, 7=adjust servo

- toggle up and release,

LED shows 1-flash (level 4, 1=reverse servo direction)

- toggle up and release,

LED lights continously and servo on P4 rotates in

the opposite direction

- Set D/F4 as momentary on/off output,

on when R/C channel 4 is low

program sequence: 3, 10, 1, 4, 1

- enter programming mode

- toggle down and release 2 times,

LED shows 3-flash (level 1, 3=On/Off Configuration)

- toggle up and release,

LED shows 1-flash (level 2, 1=P1)

- toggle down and release 9 times,

LED shows 10-flash (level 2, 10=F4/D)

- toggle up and release,

LED shows 1-flash (level 3, 1=momentary)

- toggle up and release,

LED shows 1-flash (level 4, 1=R/C chan 1)

- toggle down and release 3 times,

LED shows 4-flash (level 4, 4=R/C chan 4)

- toggle up and release,

LED shows 1-flash (level 5, 1=idle off, on when ch is low)

- toggle up and release,

LED lights continously and D/F4 switches on when Tx20v2 F2

or Tx22X S2 are pressed)

The programming table for MR603 can be found at

micronrc.co.uk/mr6xx_progtable.

Servo Throw Adjustment (top)

Servo throws (low and high end points) can be configured using a

bound transmitter, the servo centre position will always be at the mid-point

of the low and high travel.

To adjust a servo, the servo output is selected first

and then the travel adjusted using either the throttle control or

direction toggle if the throttle servo is being adjusted.

The steps below assume a Micron transmitter is being used.

If the transmitter is an aeroplane type stick transmitter then

the elevator stick corresponds to the direction toggle.

- put the receiver into programming mode (see above)

- enter the program sequence 2, P, 7, 2, where P is the output

port number (e.g. 3 for P3)

- within 5 seconds, move the control for the output being adjusted to the

end that needs adjustment:

- use the direction toggle or throttle control to increase

or decrease the servo travel:

- use the throttle control if the direction (R/C channel 3) servo

is being adjusted, or

- hold throttle knob fully CCW to decrease travel

- hold throttle knob fully CW to increase travel

- use the direction toggle for all other servos

- hold toggle down to decrease travel

- hold toggle up to increase travel

the receiver LED will flash twice per second as the servo travel is being

adjusted and stop flashing when the limit is reached.

- centre both controls to finish

the adjustment, the receiver will return to normal operating mode

after the control corresponding to the P port being adjusted

has been centred for 5 seconds.

Only one servo output can be changed at a time. Go through the

above steps to adjust a different servo output pin.

Configurations

This configuration table is for version 1.2.

For other configuration data, refer to mr6xx_version.

The pre-loaded configurations are shown below. Unless otherwise

specified when the receiver was ordered, config 1 is enabled by default.

The other loaded configurations can be selected using a

power-on configuration change

or by programming.

| Port |

1: Centre-off throttle |

2: MyLocoSound triggers on A-D (Tx22) |

3: MyLocoSound triggers on A-D (Tx20) |

4: Tx with 3-way toggle on ch2 & ch4 |

| H1 |

Centre-Off ch1 |

Centre-Off ch1 |

Centre-Off ch1 |

Low-Off ch1, dir ch3 |

| P1 |

Front Light on H1 (LED2) |

Front Light on H1 (LED2) |

Front Light on H1 (LED2) |

Momentary on ch2, high 0V |

| P2 |

Rear Light on H1 |

Rear Light on H1 |

Rear Light on H1 |

Momentary on ch2, low 0V |

| P3 |

Momentary on ch3, low 3.3V |

Momentary on ch3, low 3.3V |

Momentary on ch3, low 3.3V |

Momentary on ch4, high 0V |

| P4 |

Momentary on ch3, high 3.3V |

Momentary on ch3, high 3.3V |

Momentary on ch3, high 3.3V |

Momentary on ch4, low 0V |

| P5 |

Momentary on ch5, low 3.3V |

Momentary on ch5, low 3.3V |

Momentary on ch5, low 3.3V |

Momentary on ch5, low 3.3V |

| P6 |

Momentary on ch5, low 0V |

Momentary on ch5, low 0V |

Momentary on ch5, low 0V |

Momentary on ch5, low 0V |

| F1/A/P7 |

Front Light on H1 |

Momentary on ch3, high closed |

Momentary on ch2, low closed |

Front Light on H1 (LED2) |

| F2/B/P8 |

Rear Light on H1 |

Momentary on ch3, low closed |

Momentary on ch4, low closed |

Rear Light on H1 |

| F3/C/P9 |

Momentary on ch5, low closed |

Momentary on ch5, low closed |

Momentary on ch5, low closed |

Momentary on ch5, low closed |

| F4/D/P10 |

Latch on ch5, start open, toggle low |

Latch on ch5, start open, toggle low |

Latch on ch5, start open, toggle low |

Latch on ch5, start open, toggle low |

| LED2 |

P1 | P1 | P1 | F1 |

| Selecta |

Enabled |

Enabled |

Disabled |

Disabled |

| LVC |

Enabled |

Enabled |

Enabled |

Enabled |

| Sleep time |

1 hour |

1 hour |

1 hour |

1 hour |

| Cruise |

Enabled |

Enabled |

Enabled |

Enabled |

Other configurations

are available to special order or you can configure yourself

by programming.