This guide is designed to get you started with MR001d as quickly

as possible. More information can be found in the

user manual -

http://micronrc.uk/mr001d-info.

We strongly recommend you read this

document if you wish to change any of MR001d functionality.

If purchased with a transmitter, MR001d will be bound and ready for use;

otherwise, it requires binding to your transmitter which may be any

Spektrum DSM2 or DSMX transmitter including all of the

Micron model rail transmitters.

Once bound, the transmitter should be switched on

before the MR001d.

If the transmitter is not switched on, MR001d will automatically enter

bind mode 5 seconds after switch on; it also be manually bound using

a jumper plug on the P5/P7 signal pins.

Usage (top)

- Do not bend the receiver circuit board or use with the protective

sleeve removed.

- Ensure unused pins of P1..P7 cannot contact any metal.

- Connect to a battery or ESC output that can provide 3.5V to 8.5V

under load. Some servos can draw a heavy current when starting to move

and the voltage of a 'tired' 4 cell NiMH battery may dip below 3.5V

causing MR001d to reset. If this happens, a 5 cell NiMH battery will

give better results. A resettable fuse in the battery positive lead

is recommended to protect the battery in the event of a wiring

or component fault.

If you need to power from a single LiPo cell (e.g. because of space

reasons), a 5V or 6V booster should be used.

- If MR001d has not been supplied configured for your use, set

the throttle mode,

Selecta and Cruise control features as required

(see 'Power-On-Changes').

- If required, bind to your transmitter (see

'Binding').

- Connect your servo(s) or speed controller to the appropriate pins

(see 'Connection Diagrams')

and adjust the servo direction

and/or travel as required

(see 'Servo Adjustment').

- Fix MR001d in place and route the aerial(s) so that it

can 'see' the transmitter for best range - e.g. by routing through

a hole in the vehicle body. If the receiver is totally enclosed

within a metal body, the extended aerial version should be used,

the last 30mm is the actual aerial.

The aerial should not be cut short or made longer as this will affect

operation. It is important to perform a range check after

installation to ensure you have full control of your loco at all

positions around the layout.

Double sided foam-cored sticky tape is ideal for mounting the receiver.

Binding (top)

Manual Bind

To bind:

- with transmitter off, switch MR001d on

- wait for the LED to flash fast

- switch your transmitter on in bind mode

- the LED will stop the rapid flash, flash slowly for a while

and then light continuously

- MR001d is now bound to your transmitter

If the receiver LED does not come on solid (no flash)

within 10-15 seconds, the bind process has failed.

This can happen for several reasons and does not normally indicate a fault.

If you get a bind fail, try again after moving the Tx and Rx slightly further

apart or changing the relative orientation of the aerials.

Binding is most reliable when no other 2.4GHz transmitters are turned on.

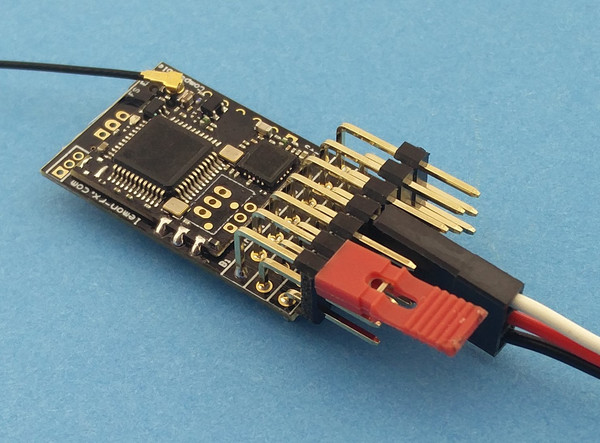

Connections (top)

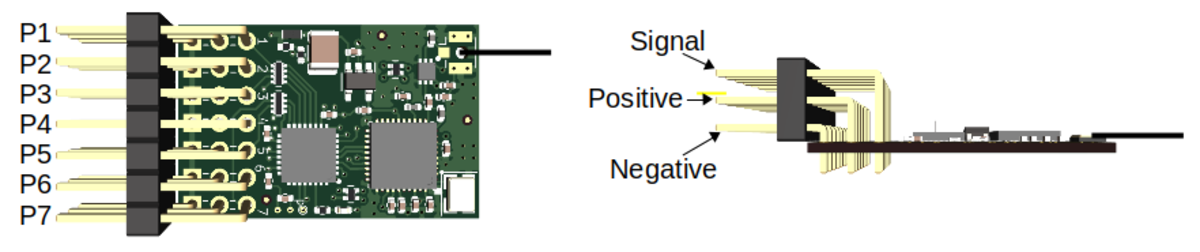

MR001d has 7 sets of output pins which can be used for servos,

speed controllers or LEDs for lighting. The pin sets, numbered

from the top of the diagram below, are 0.1" pitch to take standard R/C plugs.

An additional 4 outputs are available via an optional

JST-SH socket at the aerial end of the receiver.

Although the connector has 3.3V and 0V pins, it cannot be used for

powering a servo

as the 3.3V pin is supplied from the on-board regulator which has

insufficient current capacity for a servo.

Connections

A connector with 100mm leads is supplied when the JST-SH socket

option is selected at purchase.

Throttle Modes (top)

The transmitter's throttle control is output on P1 (default configuration,

may be changed by programming) to drive a regulator

servo or an external speed controller.

The throttle mode is used mainly to control how the directional lights

operate and to close the throttle if the emergency stop feature is enabled

or cruise control is disabled.

Also, there will be no output from P1 until MR001d has received a valid

stop throttle signal.

The 3 throttle modes are:

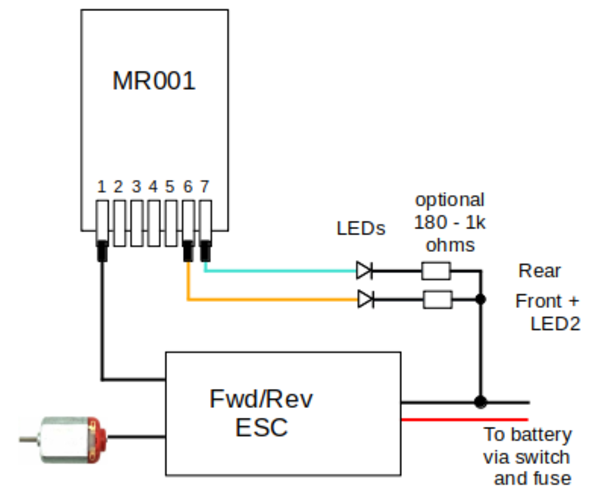

- centre-off

-

Forward and reverse on one transmitter control with stop in the centre.

Best used with an external forward/reverse speed controller

connected to P1 as shown in the 'ESC Connection' diagram.

MR001d is powered from the speed controller's 5V output.

This is the default mode and MR001d will be supplied centre-off

unless otherwise requested.

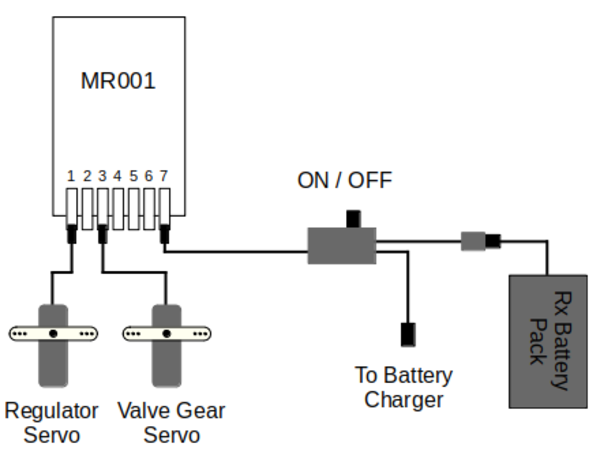

- low-off

-

Separate transmitter controls for speed and direction which are output

on P1 and P3 (R/C channels 1 and 3).

This mode is suitable for most live steam locos.

- low-to-centre

-

Separate speed and direction transmitter controls are combined into one

forward/reverse output on P1. This mode is intended for

battery electric locos where the user prefers separate controls or

who wants to use a transmitter for both live steam and battery locos.

The throttle control min and max positions will require calbration the

first time MR001d is switched on in this mode. After initialisation,

the LED will display a repeated pattern of 1 long flash followed

by 1 short flash. Move the transmitter throttle control to its minimum

CCW position (stop) then move it to the maximum CW position (full

speed) and finally back to stop. The LED will then light continously.

ESC Connection

Servo Connection

Power-on-Changes (top)

Some MR001d configuration changes may be done using one or more jumpers

placed on the P1..P7 signal pins before the receiver is switched on.

The LED will display a flash pattern corresponding to the selected

change. The table below summarises the available changes and the

associated flash patterns.

The changes all cycle though the flash counts while the jumper is installed.

Each flash count is repeated once (i.e. shown twice)

and then increments to the next, cycling back to 1 when the maximum is reached.

When the desired flash count has been shown,

removing the large jumper acknowledges the selection by showing a rapid flash. There will be a short delay between removing the

jumper and the rapid flash due to the time taken to write the

changes to permanent memory.

The receiver should be powered off when the rapid flash starts.

If you switch off before removing the jumper connection,

the configuration is not changed.

If you switch off after removing the jumper and before the rapid LED flash,

the receiver data is likely to be corrupted and you should perform a reset.

It is recommended to do a backup after making any other changes (including

any programming via a transmitter

- see http://micronrc.co.uk/mr001d-progtable).

| Change | Large Jumper | Small Jumper |

LED indication

* = default setting |

|---|

| Reset & Backup |

P1/P3 | - |

n-flash where 'n' is:

1: do nothing

2: reset

3: backup

4: disable/enable ch2/ch4 programming

|

| Configuration Select |

P1/P3 | P4/P5 |

n-flash where 'n' is the configuration number |

| Throttle Arm Mode |

P1/P3 | P5/P6 |

This controls the way that the throttle output (normally P1) behaves

after switch on:

1-flash = disabled (output follows Tx throttle immediately)

2-flash = enabled (output disabled until Tx throttle at stop)

*

|

| LED2 |

P2/P4 | - |

1-flash - disabled

2-flash = normal, not Select and not Cruise *

3-flash = Selecta & Cruise

4-flash= always |

| Throttle Mode |

P3/P5 | - |

1-flash = centre-off (thr=ch1) *

2-flash = low-off (thr=ch1, dir=ch3)

3-flash = low-to-centre (thr=ch1, dir=ch3)

|

| Selecta |

P4/P6 | - |

1-flash = disabled *

2-flash = enabled |

| Cruise Control |

P4/P6 | P1/P2 |

1-flash = disabled, stop in 4s after signal loss

2-flash = enabled, continue running while no signal * |

| Bind |

P5/P7 | - |

rapid flash indicates bind mode |

P1/P3 - Reset & Backup |

P1/P3, P4/P5 - Config Select |

P1/P3, P5/P6 - Throttle Arm Mode |

P2/P4 - LED2 |

P3/P5 - Throttle Mode |

P4/P6 - Selecta |

P4/P6, P1/P2 - Cruise |

P5/P7 - Bind |

See the user manual for more details.

Servo Adjustment using Jumper Plugs (top)

Servo throws (low and high end points) and reversing can be configured

in 2 ways:

- using the small and large jumpers for adjusting P1..P7

- by using a transmitter for adjusting P1..P10

Use of jumper plugs will be described here,

see http://micronrc.co.uk/mr001d-info for details on how

to use a transmitter to adjust servo throws.

WARNING: never place the small jumper across

the positive (middle row) and negative (bottom row) pins. This will short

the battery.

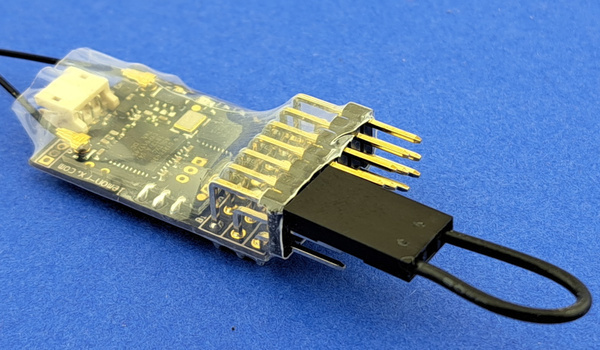

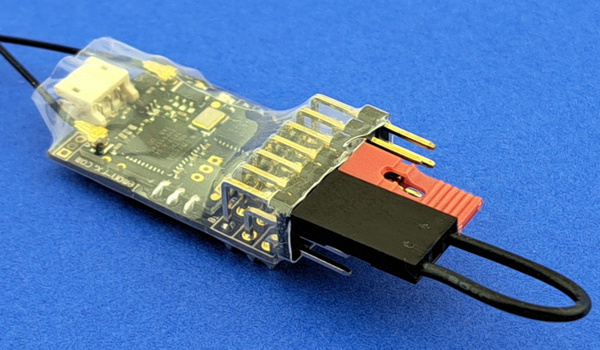

Step 1 - select a servo output to adjust

Use the small jumper plug to select a servo output to adjust.

It is placed across the signal pin (top row) to be adjusted

and the adjacent signal pin.

For example, to select P1 (throttle),

place the small jumper plug across signal pins 1 and 2 as shown in the image

(the black connector in the image is the battery plugged into P4).

The standard MR001d setup has servo outputs on P1..P5. If your receiver

has servo outputs on P6 and/or P7, these may also be adjusted - P7

requires use of both small and large jumper plugs.

Steps:

P1 selected

- MR001d must already be bound to your transmitter

- receiver off and transmitter on

- place the small jumper and then connect the battery:

- P1: small on P1/P2, battery on P4

- P2: small on P2/P3, battery on P4

- P3: small on P3/P4, battery on P1

- P4: small on P4/P5, battery on P1

- P5: small on P5/P6, battery on P4

- P6: small on P6/P7, battery on P4

- P7: small on P1/P2 and large on P5/P7, battery on P4

- the LED will flash a sequence twice to indicate the selected pin set

and then flash rapidly - e.g. flash pause flash pause rapid for P1,

flash flash pause flash flash pause rapid for P2, and so on

Note: if the selected pin is not currently configured as a servo

the LED will not flash the pin number sequence and go immediately

to rapid flashing; the receiver must be switched off and back on again

- remove the small jumper plug when the LED is flashing rapidly,

the LED will flash slowly (1 per second).

Do not remove the battery

- connect a servo, this will respond to the transmitter control,

no other output pin is active

The servo output is now selected.

Jumper plugs are used on P6 and P7 (or P1 and P2 for adjusting P6 or P7)

to reverse the servo or adjust the travel end points.

Reversing or end point adjustment can be repeated as often as desired

while the servo is selected. To stop the process, remove power from the

receiver.

Reverse servo direction

The small jumper plug is placed across signal pins P6 and P7

(or P1 and P2 if adjusting a servo on P6 or P7).

Steps:

- select servo output to adjust and plug servo in

- place the small jumper across signal pins P6 and P7

(or P1 and P2 for a servo on P6 or P7)

- the LED will flash rapidly

- remove the jumper and the LED will stop flashing

- the servo will respond to transmitter controls in the opposite

direction to previous

The servo direction will reverse each time the procedure is executed.

Adjust servo travel

Servo travel end points can be increased or decreased using the large

jumper plug on P6 (decrease) or P7 (increase)

- P1 and P2 for servos on P6 or P7.

The adjustment is done in small steps every ½ second and the

LED flashes for each step.

To make an adjustment:

- move the servo to the low or high end using the transmitter control

- use the large jumper to make changes:

- on P6 to decrease the throw (P1 for servo on P6/P7)

- on P7 to increase the throw (P2 for servo on P6/P7)

- either remove the jumper or move the servo away from the end to

stop the adjustment

The LED will stop flashing and the servo will stop moving when the

adjustment limit is reached.

- The limit for decrement is the mid point

of travel so, if an end point is decreased to the maximum amount,

there will be no servo travel in that direction when the transmitter

control is moved.

- The limit for increment is the maximum signal value.

Take care: not all servos will respond to the maximum

range of servo signal values; stop decrementing when the servo

stops moving even though the LED is still flashing.

When the increment or decrement jumper is removed, the LED will flash

rapidly for 2 seconds while the servo offset is being saved. You may

continue adjusting after the flashing has stopped.